For demanding applications, you may need to take your compressor’s pressure levels to new heights and maximise productivity with high-pressure boosters. While the pressurised air supplied through a standard compressor is more than sufficient for many industrial processes, certain applications require pressure levels to be taken up a notch (or 10). In these instances, adding a high-pressure booster is the ideal solution – and carries with it an abundance of efficiency, safety and productivity benefits.

As the name suggests, a booster ‘boosts’ or increases the pressure levels of a primary feed air compressor. Never a stand-alone product, it works in tandem with the primary unit by taking the air and passing it through additional compression stages, creating up to 10 times more pressure. For example, Atlas Copco, market-leader in compressed air solutions, offers boosters that can increase pressure from a standard unit to anywhere between 69 and 345 bar.

Versatility and profitability

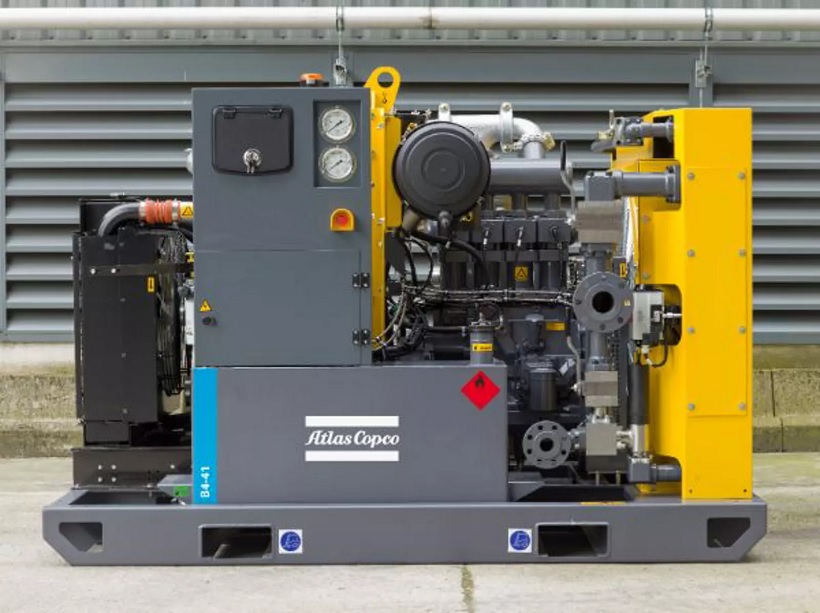

There are air, nitrogen and gas treatment booster solutions for all high-pressure applications, which are ready to be integrated into a wide range of industrial processes. Designed to suit the most demanding of operations, they are particularly useful for deep geothermal, exploration and water well drilling, and pipeline testing. All Atlas Copco models are standard equipped with a lifting eye and forklift slots and weigh as low as 6,500 lbs, meaning they can be transported to even the most remote offshore projects with ease.

Booster-controller

Using a booster that offers versatility is also key to avoiding wasted energy. Atlas Copco’s Xc4004 Smart air controller, for instance, enables users to easily define the booster’s output pressure with a touch of the button. In a high-pressure drilling application, the drill speed can efficiently be increased, reducing the cost-per-meter drilled, thereby improving overall profitability. The modular design of the company’s dual stage boosters also allows the user to change from dual to single stage, giving more control of the utilisation rate of their investment.

Maximum safety, minimum maintenance

The ease and speed of a booster’s maintenance and servicing is impacted by the quality of its components, the tools needed, and the accessibility of maintenance-prone components (such as the pumper block or the drain points). Atlas Copco boosters can be maintained by one service technician within four hours, as the standard components are easily accessible and do not require a crane or special tools.

Boosters should also include all necessary safety mechanisms – both visual and auditory – that adhere to legislative requirements. Atlas Copco’s state-of-the-art Xc4004 controller continuously monitors all vital parameters of the booster, and in case of pending failure, will protect the user’s investment by automatically shutting the unit down to avoid damaging core components. The technology even indicates when preventive maintenance is required, maximising uptime.

These high-pressure, ingenious machines are ultimately much more than just a booster. And with a broad range of both standard and custom-designed models available on the market, any demanding application can reap the benefits of integrating boosters into their compressed air packages, no matter how unique our tough the conditions.